What Quality Tests Do We Perform on Toilet Seats and Covers?

We have our own in-house laboratory where we carry out usage and surface tests to guarantee the durability and appearance of our toilet seats and covers

Sergi Morales

Quality Manager

At COMSAN, we see quality as one of our core values. One of our main goals is to meet the needs and expectations of our customers. That is why, at every stage of our production process, we apply strict validation standards before reaching the final testing phase prior to commercialization.

This ensures that our toilet seats and covers are designed to meet international quality standards. We also offer the option to certify products according to the corresponding standards: NF, JC, or BSI.

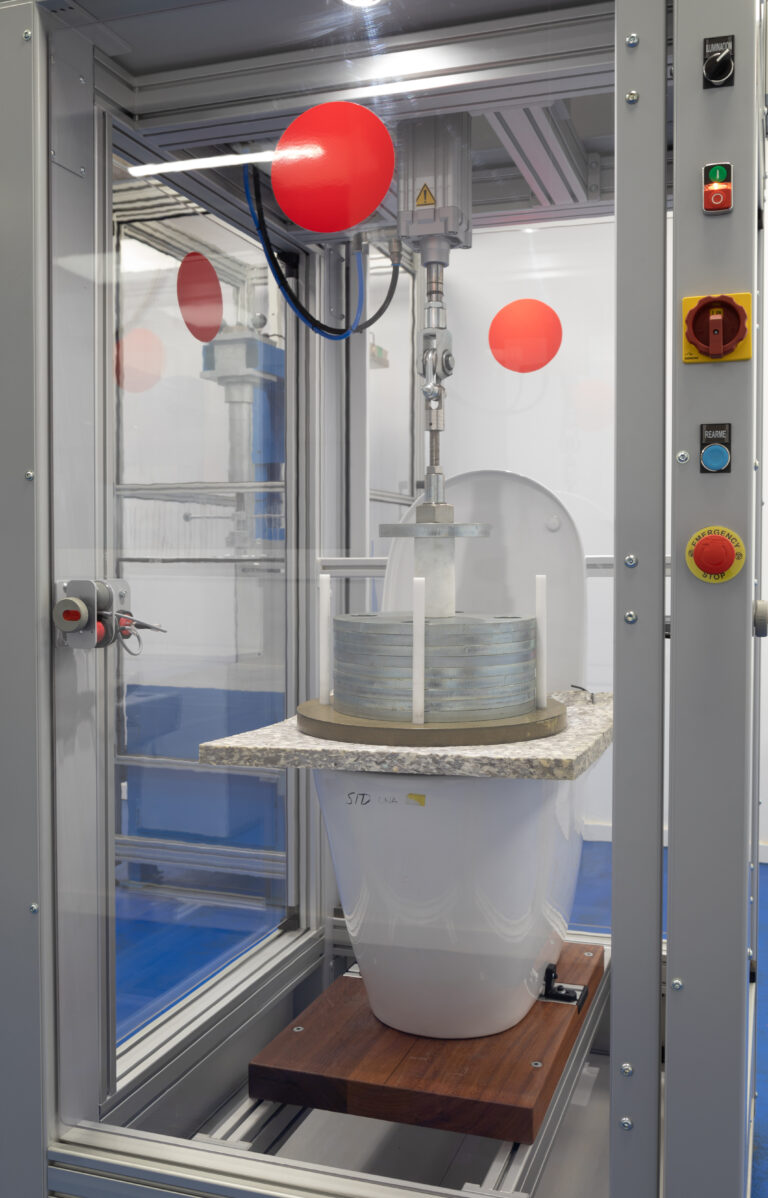

Having our own laboratory on-site allows us to subject our toilet seats and covers to the same quality tests required by international standards. Thanks to these facilities, we can guarantee that our products meet the necessary technical requirements to pass the highest quality benchmarks.

Mechanical Tests: Strength and Durability

These tests reproduce real and extreme conditions of toilet seat use to ensure years of trouble-free performance.

- Static Load Test: This test checks that the seat and cover can withstand the weight of a user without damage.

- How it is done:

- With the seat mounted, a minimum load of 150 kg is applied for 3 minutes.

- The load is distributed evenly across the center of the cover or seat using a rubber sheet to protect the surface..

- Acceptance criteria: No breakage, cracks, or permanent deformation greater than 1 mm.

- Ojective: Ensure that the seat remains stable and safe even under high loads.

- Mechanical Strength Test: This test evaluates the overall robustness of the set (seat and cover) under daily use.

- How it is done:

- The seat and cover are mounted on a rigid support, as they would be installed on a toilet.

- The set is dropped from an 85° angle around 30,000 times, simulating opening and closing over years of use.

- Every 10,000 cycles, the hinges are checked for loosening; if necessary, they are retightened, and the test continues.

- Acceptance criteria: No breakage, excessive loosening, or axial play greater than 1 cm at the end of the test.

- Objective: Ensure the cover withstands tens of thousands of openings and closings without compromising stability or safety.

- Dynamic Load Test: This test subjects the seat to repeated impacts, simulating sudden drops and intensive use..

- How it is done:

- The cover is mounted on the toilet or on a rigid surface.

- A weight of at least 75 kg is dropped repeatedly from a height of 30 mm, with an intermediate foam plate to absorb impact.

- 30,000 drops are performed at a rate of 10 to 15 cycles per minute.

- Acceptance criteria: No cracks, fractures, or deformations after the full cycle.

- Objective: Reproduce accidental impacts and ensure the seat maintains its integrity.

Surface Tests: Hygiene Guarantee

The quality of a toilet seat is not only measured by its mechanical strength – it must also maintain its appearance, hygiene, and durability in an environment exposed to humidity, cleaning products, and constant use. At COMSAN, we perform several surface tests to ensure that the cover continues to look and function properly for years.

- Stain and Chemical Resistance Test

- How it is done:

- Drops of standardized reagents are applied to the surface: Sulfamic acid (15 g/l), Caustic soda (NaOH, 100 g/l), Bleach (minimum 5% active chlorine), and Uric acid (1.6 g/l).

- The drops are covered with watch glasses and left for 2 hours at 23 °C.

- The area is then cleaned with demineralized water. If stains remain, the area is cleaned again with a standardized cleaning device, and if necessary, with a mild abrasive.

- Acceptance criteria: The surface must show no permanent stains or deterioration that affects hygiene or appearance.

- Objective: Ensure that the cover resists common cleaning products without losing shine or color.

- Moisture Resistance Test

- How it is done:

- The cover is placed in a chamber at 50 °C and 95% relative humidity for 200 hours.

- It is then dried for 24 hours at room temperature and visually inspected.

- Acceptance criteria: No swelling, cracks, or degradation in joints or edges.

- Objective: Ensure the cover withstands condensation and the humid bathroom environment without deformation.

- Coating Adhesion Test

- How it is done:

- A cross-cut is made on the painted or lacquered surface.

- Standardized adhesive tape is applied and quickly removed.

- The coating is inspected to see if it detaches.

- Acceptance criteria: Classification index must be ≤ 2 (ISO scale), meaning minimal peeling is acceptable.

- Objective: Ensure that paints, lacquers, or decorative finishes remain firmly in place without flaking.

- Scratch Resistance Test

- How it is done:

- Inspección visual bajo condiciones normalizadas de luz y distancia.

- In some cases, standardized tips or hardness pencils are used as complementary internal quality control tests.

- Acceptance criteria: No scratches should be visible in hygienic or primary areas, though some are acceptable in secondary or hidden areas.

- Objective: Ensure that the cover maintains an impeccable finish in areas that are in direct contact with the user.

At COMSAN, we test every toilet seat and cover to ensure they are strong, safe, hygienic, and have a flawless finish that lasts for years. Thanks to our strict quality controls, we can confidently say that our products meet the most demanding international standards.